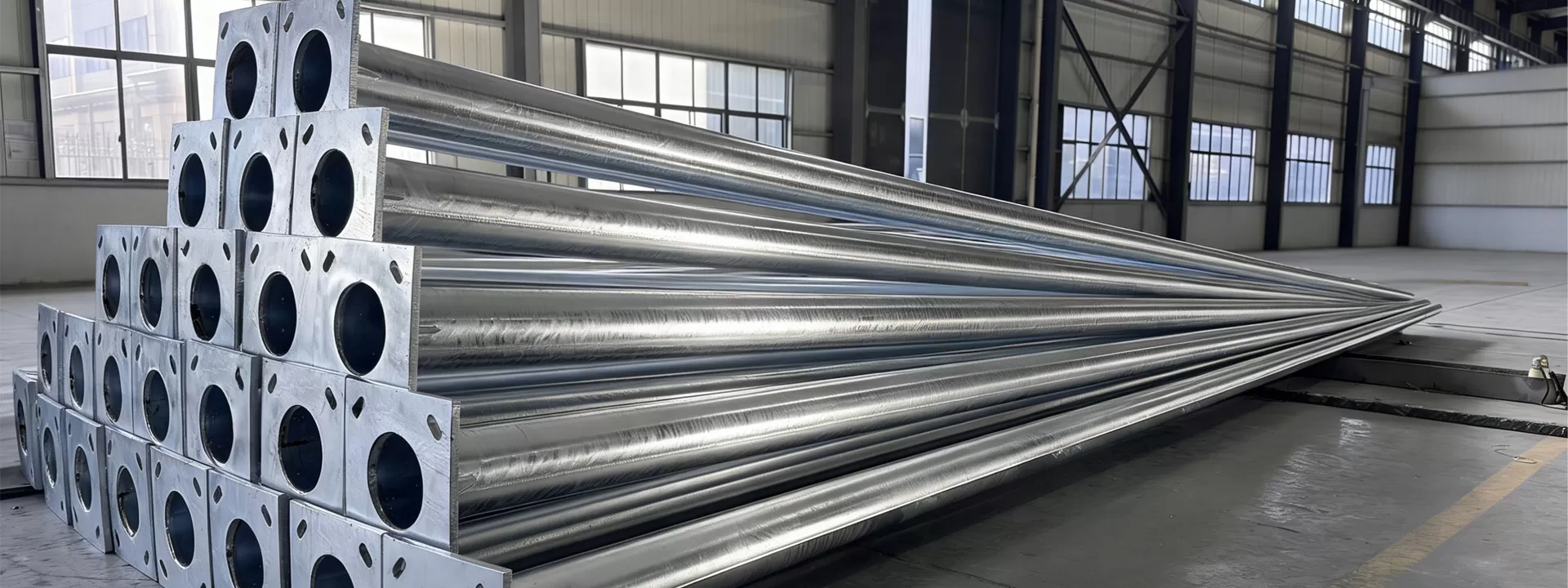

Specification of Galvanized Pole

| Material | Commonly Q345B/A572, Q235B/A36, Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, ST52 |

| Height | 5M | 6M | 7M | 8M | 9M | 10M | 12M |

| Dimensions(d/D) | 60mm/150mm | 70mm/150mm | 70mm/170mm | 80mm/180mm | 80mm/190mm | 85mm/200mm | 90mm/210mm |

| Thickness | 3.0mm | 3.0mm | 3.0mm | 3.5mm | 3.75mm | 4.0mm | 4.5mm |

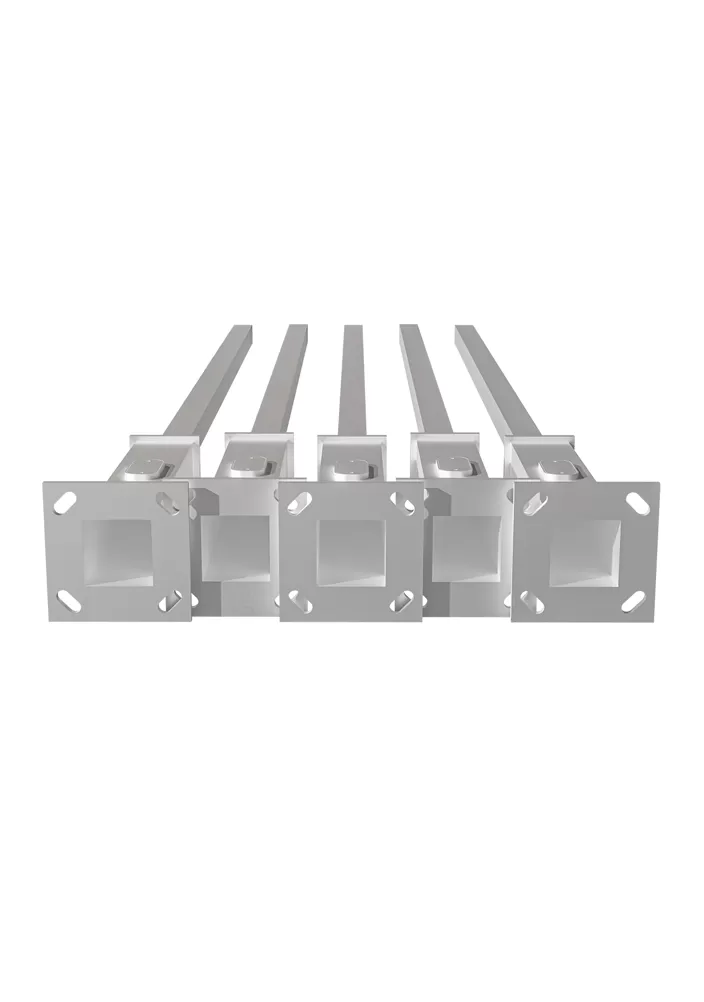

| Flange | 260mm*14mm | 280mm*16mm | 300mm*16mm | 320mm*18mm | 350mm*18mm | 400mm*20mm | 450mm*20mm |

| Tolerance of dimension | ±2/% |

| Minimum yield strength | 285Mpa |

| Max ultimate tensile strength | 415Mpa |

| Anti-corrosion performance | Class II |

| Against earthquake grade | 10 |

| Surface treatment | Hot-dip Galvanized and Electrostatic Spraying, Rust Proof, Anti-corrosion performance Class II |

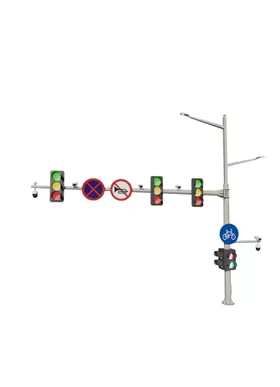

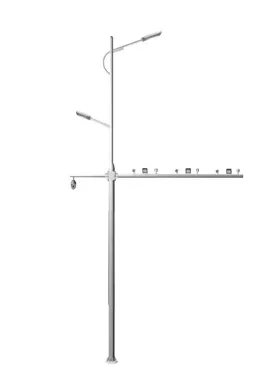

| Shape Type | Conical pole, Octagonal pole, Square pole, Diameter pole |

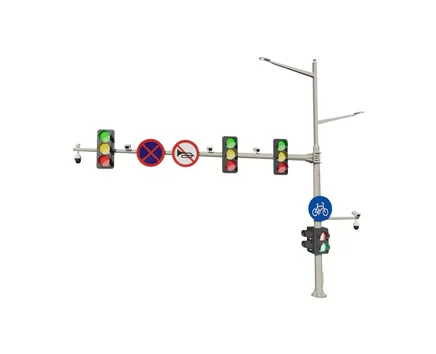

| Arm Type | Customized: single arm, double arms, triple arms, four arms |

| Stiffener | With a big size to strengthen the pole to resist the wind |

| Wind Resistance | According to local weather conditions, the General design strength of wind resistance is ≥150KM/H |

| Welding Standard | No crack, no leakage, no welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. |

| Hot-Dip Galvanized | The thickness of hot-galvanized is 60-100um. Hot Dip Inside and outside surface anti-corrosion treatment by hot dipping acid. which is in accord with BS EN ISO1461 or GB/T13912-92 standard. Designed life of the pole is more than 25 years, and the galvanized surface is smooth and the same color. Flake peeling hasn't been seen after the maul test. |

| Anchor bolts | Optional |

| Material | Aluminium,SS304 is available |

| Passivation | Available |

What are Galvanized Poles?

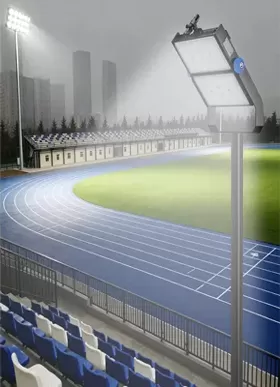

Poles that have undergone a galvanizing process are known as galvanized poles. A homogeneous zinc layer is created on the surface of a black pole by hot-dip galvanizing. With a thickness of at least 80 micrometers and an outdoor lifespan of up to 20 years, this zinc layer is firmly bonded to the base material. Phoebus galvanized poles, which are frequently found in streets, squares, and parks, are appropriate for challenging conditions like rainy, high humidity, and coastal regions with high salt spray. To improve their appearance, they can receive additional powder coating.

Why Choose Phoebus Galvanized Poles?

1. Refined Surface Treatment

Powder coating can be applied as needed after galvanizing, making color customization simple. The surface is easy to clean, smooth, and resistant to dirt.

2. Easier Installation

By ensuring a tight fit with the foundation through precise drilling, thickened and reinforced flanges greatly increase on-site installation efficiency and reduce construction time.

3. More Attentive Service

Dedicated staff members offer complete support, from initial specification customization and solution coordination to subsequent installation guidance and troubleshooting. There are comprehensive qualification documents available, including material reports and testing certificates.

Technical Support, Installation Guidance, and After-Sales Service

Technical Support

We provide initial light pole selection advice and customize galvanizing processes, heights, and accessory combinations based on usage scenarios; we offer full technical support and answer all your questions, providing professional construction drawings and technical parameter specifications, and assisting with project approvals.

Installation Guidance

We provide installation guidance videos, including foundation pouring, light pole hoisting, wiring connections, and overall commissioning.

After-Sales Guarantee

Free replacement and repair of defective parts for the duration of the product's warranty; lifetime technical consultation and maintenance advice; frequent follow-up visits to comprehend product usage; and support for on-demand spare part supply to meet future maintenance consumable needs.