- > Split Solar Street Light

- > All in One Solar Street Light

- > Solar Pole Light

- > Smart Solar Street Light

- All in Two Solar Street Light

- Solar Street Light with Lithium Battery

- Solar Street Light with Gel Battery

- New All in One Solar Street Light

- All in One Solar Street Light with CCTV

- Auto Clean All in One Solar Street Light

- Intelligent Control All in One Solar Street Light

Cases

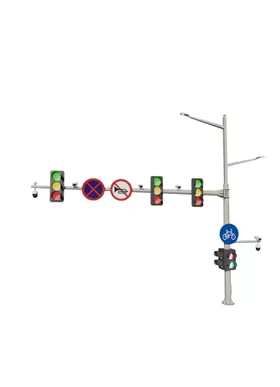

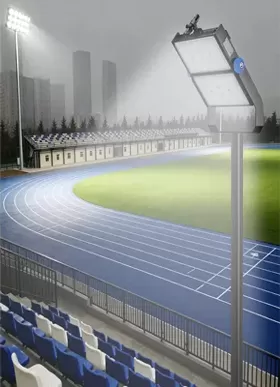

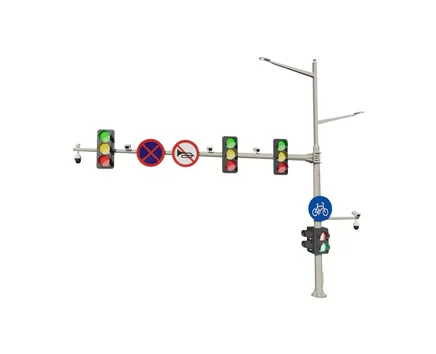

- Stadium Lights

- All in One Solar Street Lights

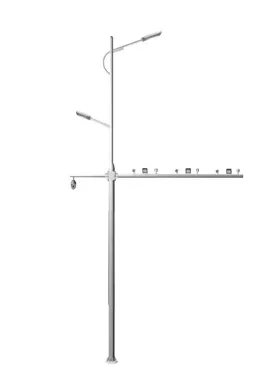

- Decorative Light Poles

- Split Solar Street Lights

- Guizhou Province Rural Revitalization Comprehensive Lighting Project | Solar Street Light OEM Cooperation Case

- Abuja Airport Peripheral Road Project | International OEM Case of Smart Solar Street Lights

- Long-Term Brand Partnership Case | Strategic ODM / OEM Cooperation in Smart Photovoltaic Lighting

En

What are you looking for?